The granulator, a component of ice cream on stick machines, which prevents production cycle interruptions and product waste.

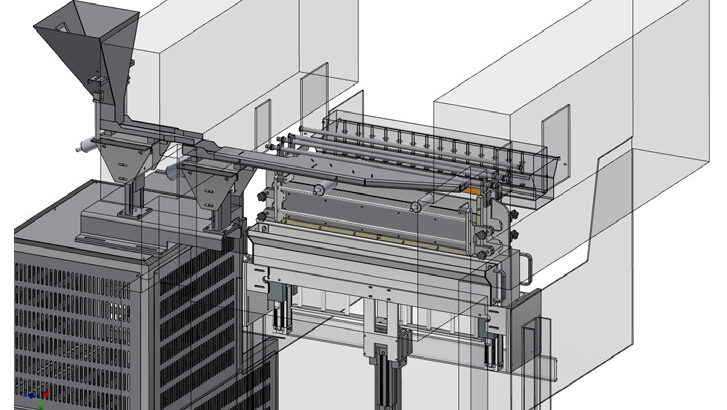

The dry coater, a component of ice cream stick machines, prevents production cycle interruptions and product waste.

Gritting -the coating of ice cream frosting with granules or decorations is a critical process: if not handled properly, it can lead to errors, wasted ingredients (which come at a cost), and disruptions in the production cycle.

The dry coater is designed to coat ice cream with dry, granular ingredients such as nuts, pistachios, candies, etc. It is positioned on the third descent of the extraction (descent is standard) after the chocolate.

Electropneumatic and stainless steel servo operation, which works so that dry ingredients enter the main hopper and with a vibration system feed the main tank.

In the main tank, when the freshly chocolate-covered ice creams arrive, the central component descends along with the products, thanks to a servo-controlled system. The two outer walls inside the tank move upward thanks to two pneumatic cylinders. In this way we can push the dry ingredients toward the top part of the ice cream to create the most uniform granulation possible.

The dry coater hopper can be equipped with a special level capacity system that controls the automatic vacuum feeding system from a specific tank.

From the PLC we can completely manage the whole system, from speed to product size, automatically or manually depending on the machine that mounts the dry coater.